◆Vertical Quartz Boat◆

Vertical Quartz Boat for semiconductor manufacturing equipment.

Various vertical and horizontal shapes are available.

◆Quartz Pedestal◆

Parts of any shape can be produced by welding together quartz rod or tubes.

◆Bell Jar◆

High-precision welded bell jar with minimized variation in thickness.

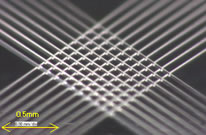

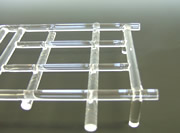

◆Gas Distribution Plate◆

A quartz plate with precisely drilled holes.

Can also handle precise drilling of minute φ0.1-mm holes.

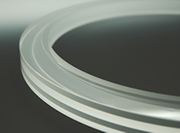

◆Quartz Ring◆

Ring products can be manufactured in various forms and shapes.

◆Quartz Reaction Tube◆

Various large size reactor tubes for 300mm wafers process can be manufactured.